Predictive Maintenance for Food & Beverage

Boost efficiency and save money with our advanced predictive maintenance system tailored for the food & beverage industry.

Harness the Advantages of Sophisticated prescriptive maintenance for Cement Production

Manufacturing Challenges

Insights Demonstrating Our Excellence in Food & Beverage condition monitoring

Our dedication to advancing Food & Beverage operations through digital innovation and predictive maintenance is evident in the substantial improvements our clients have realized. Food & Beverage producers have transformed their operations by implementing our tailored predictive maintenance software, securing notable financial and efficiency benefits.

Maximize Production Efficiency: Transform your production processes with immediate access to data on equipment performance and capacity planning. Our custom software solution enables you to effortlessly manage your industry assets, ensuring their optimal use. Investing in this level of precision control is critical for enhancing your operations, leading to better resource management and increased production rates.

Reduce Costs: Significantly decrease cycle times and increase material efficiency with intuitive reporting and analytics tools designed for Food & Beverage condition monitoring. These specialized tools incorporate cutting-edge predictive maintenance strategies to optimize operations. Adopting preventative maintenance not only safeguards your assets from unexpected failures and costly repairs but also promotes a more efficient and cost-effective production process.

Enhance Equipment Management: Improve your production equipment setups and transitions with digital solutions tailored for operators to meet goals more efficiently. These tools enhance overall operational productivity in Food & Beverage manufacturing, making it easier to monitor progress and quickly adjust strategies. Leveraging this approach maximizes your investment in Food & Beverage technology and ensures the best possible resource use, resulting in a more profitable and eco-friendly operation.

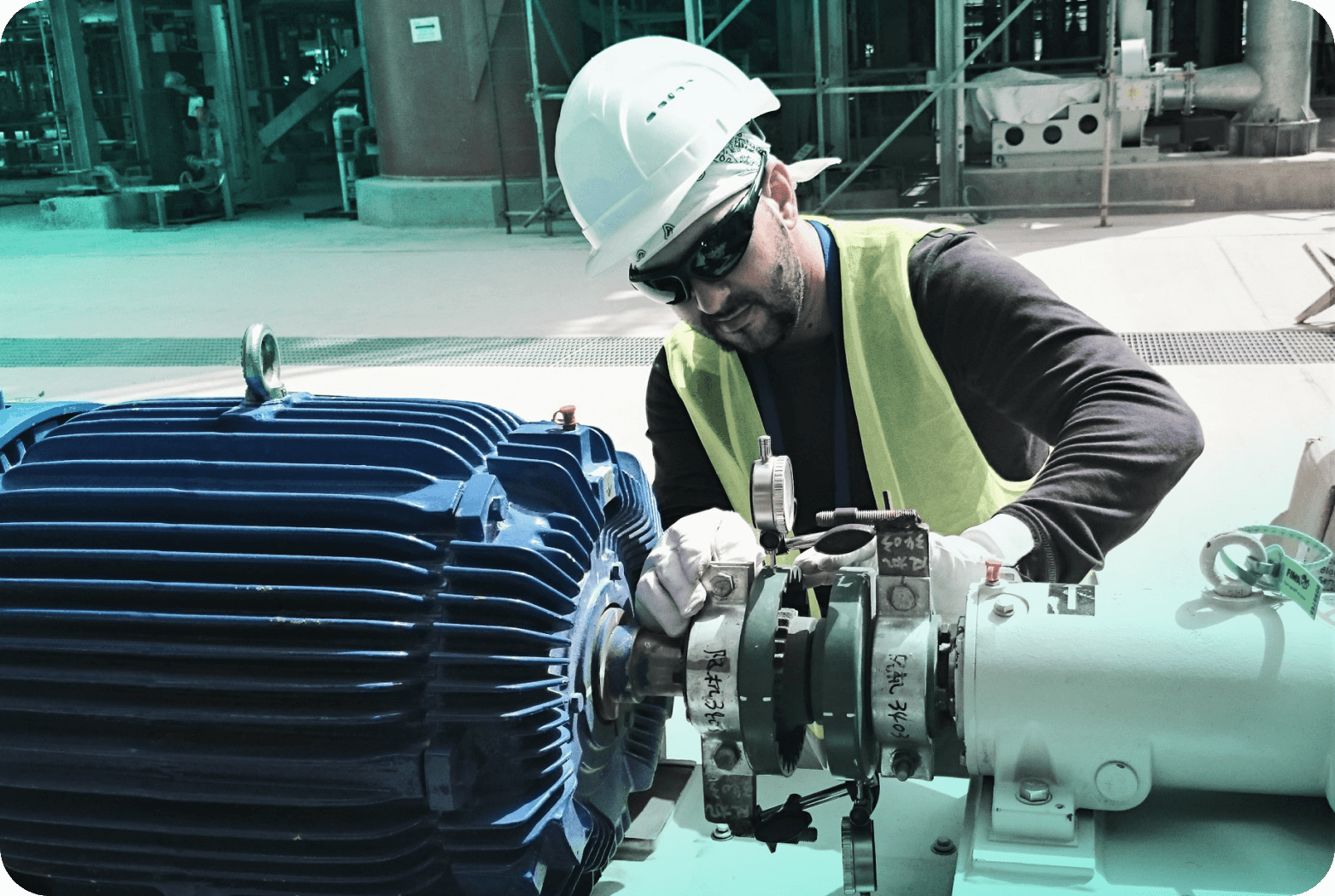

Our Continuous Asset Monitoring Solutions Keep Critical Food & Beverage Production Equipment Running Smoothly to Prevent Downtime and Reduce Maintenance Costs

Revitalize Your Food & Beverage Production Processes Today

Embark on the next era of Food & Beverage manufacturing with our state-of-the-art predictive maintenance software. Custom-designed to boost efficiency, cut costs, and increase productivity, our solution is the gateway to achieving operational excellence.

Unlock the power of predictive maintenance and real-time data analytics. Transform your production into a model of efficiency and profitability.

Optimized Equipment Reliability

Through predictive maintenance and continuous monitoring, ensure your Food & Beverage production assets continually operate optimally, reducing the risk of unexpected downtime.

Cost Savings

Our software fine-tunes maintenance schedules and enhances process efficiencies, decreasing overhead expenses and elevating your bottom line.

Improved Production Efficiency

Leverage insights from data analytics and streamlined operations to achieve unmatched levels of production efficiency, setting new standards in Food & Beverage manufacturing prowess.

Book a demo

Case Studies

These teams are rockstars in their organizations and we celebrate their work.